ZJQ double stirring submersible sediment pump suction sand river bottom dredging sand pump

Quik Detail

| Warranty | 1years |

|---|---|

| Customized support | OEM, ODM, OBM, Software reengineering |

| Brand Name | Pansto Pump |

| Model Number | ZJQ |

| Place of Origin | Hebei, China |

| Application | Commercial Buildings, Mining industry |

| Power Source | Electric |

| Pressure | Low Pressure |

| Structure | Single-stage Pump |

| Outlet Size | 40-300mm |

| Voltage | 380v |

| Power | 2.2-630kw |

| motor | Three phase asynchronous motor |

| Product name | Submersible Slurry Pump |

| Usage | Sludge |

| Standard or Nonstandard | NEMA Standard |

| Application scope | Mining Industry |

| Material | Cr27 |

| Packing | Plywood Packaging |

| Pump body | Cast Iron |

| Feature | Long Life |

| Function | Slurry Transmission |

Product Detail

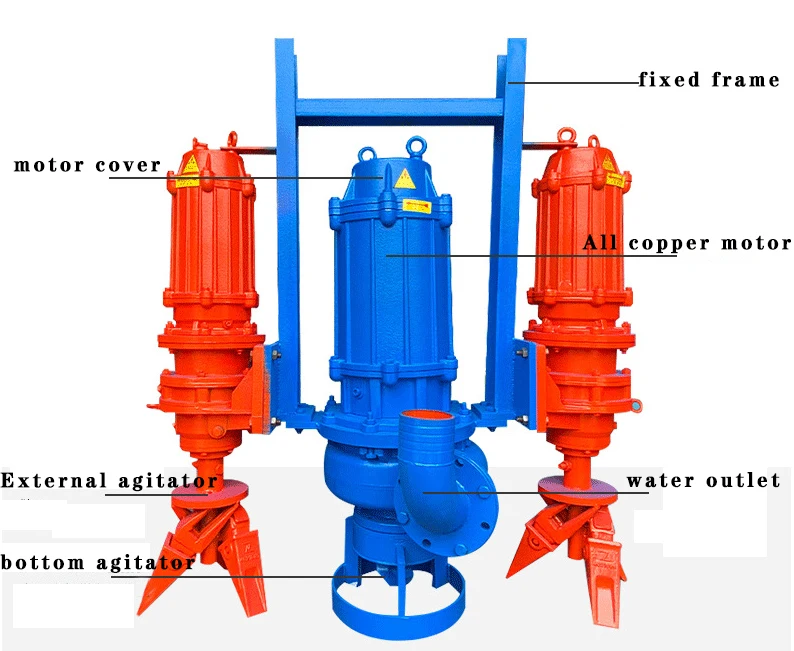

ZJQ double stirring submersible sediment pump suction sand river bottom dredging sand pump

The Ultimate Solution for Vertical Slurry Transport

ZJQ double stirring submersible sediment pump suction sand river bottom dredging sand pump are specifically engineered to handle the transfer of abrasive and high-density slurries in vertical sump applications. With their innovative design and exceptional performance, these pumps provide reliable and efficient slurry transport in various industries.

Key Features:

- Robust Design: ZJQ double stirring submersible sediment pump suction sand river bottom dredging sand pump are constructed with durable materials that are resistant to wear, corrosion, and impact, ensuring long-lasting performance even in the harshest environments.

- Vertical Configuration: The pumps are designed for installation in vertical sumps or tanks, making them suitable for applications where space is limited or where submerged operation is required.

- High Efficiency: Equipped with advanced hydraulic technology, these pumps offer high efficiency, optimizing the delivery of slurries while minimizing energy consumption.

- Wide Range of Applications: ZJQ double stirring submersible sediment pump suction sand river bottom dredging sand pump are widely used in industries such as mining, mineral processing, coal preparation, chemical processing, and more. They can handle abrasive, corrosive, and high-density slurries effectively.

- Versatile Performance: With a range of impeller options and customizable configurations, these pumps can adapt to various operating conditions and handle a wide range of solids concentrations and particle sizes.

- Reliable Operation: ZJQ double stirring submersible sediment pump suction sand river bottom dredging sand pump are designed and manufactured to ensure reliable performance and minimal downtime. Their robust construction and precision engineering make them dependable even in demanding applications.

- Easy Maintenance: The design of these pumps allows for easy access to critical components, simplifying maintenance tasks such as impeller and liner inspection or replacement.

Applications:

ZJQ double stirring submersible sediment pump suction sand river bottom dredging sand pump are used in a wide range of applications, including:

- Mining and Mineral Processing: They are ideal for transporting slurries containing minerals, ores, and other solid particles encountered in mining operations.

- Coal Preparation: ZJQ double stirring submersible sediment pump suction sand river bottom dredging sand pump efficiently handle the transportation of coal slurries, contributing to the coal washing and separation processes.

- Chemical Processing: They effectively handle corrosive slurries encountered in chemical production and processing.

- Aggregate Processing: These pumps play a vital role in handling sand, gravel, and other abrasive materials in aggregate processing plants.

- Power Generation: ZJQ double stirring submersible sediment pump suction sand river bottom dredging sand pump are used for transporting fly ash, bottom ash, and other residues generated during power plant operations.

Choose ZJQ double stirring submersible sediment pump suction sand river bottom dredging sand pump for reliable, efficient, and low-maintenance vertical slurry transport. Contact us today to discuss your specific requirements and find the perfect solution for your application.