Submersible vertical slurry pump price, mud pump

Quik Detail

| Warranty | 1 year |

|---|---|

| Customized support | OEM, ODM, OBM |

| Brand Name | NNT |

| Model Number | spare parts |

| Place of Origin | Hebei, China |

| Application | Metal and Equipment Manufacturers, Mining industry, Wastewater Transport and Flood Control |

| Horsepower | 20-266 hp |

| Power Source | Electric |

| Pressure | 1-3 bar, High Pressure sand slurry pump |

| Structure | Single-stage Pump |

| Outlet Size | 40-300 mm |

| Voltage | 380/400/415V, etc . |

| Power | 15-200 kw, Electric slurry pump |

| name | Vertical electric pump for river sand dredging |

| material | high chrome alloy and rubber |

| theory | centrifugal slurry pump |

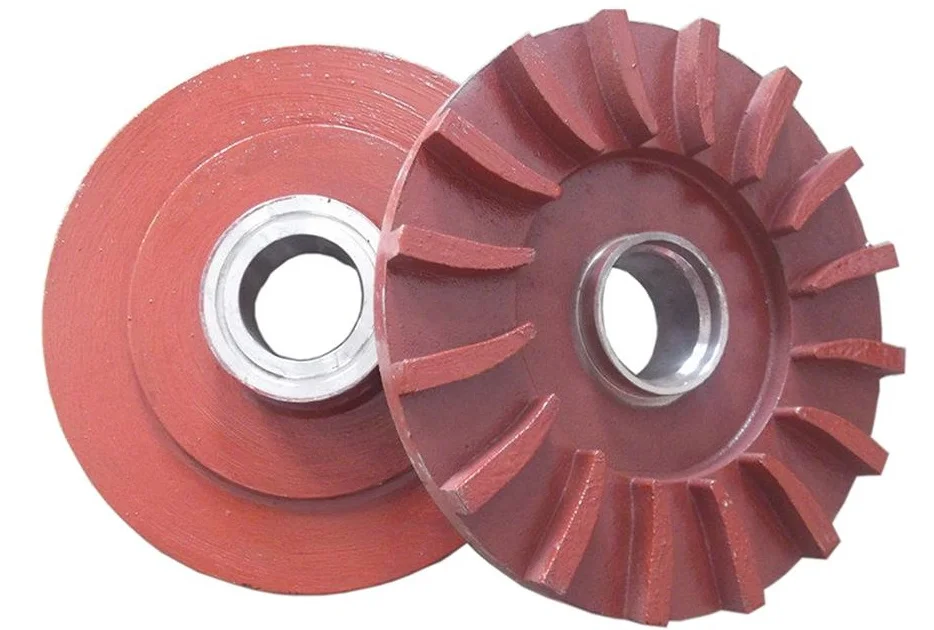

| type | closed impeller/open impeller |

| vane | 3,5 |

| pump models | NH, HH, ZJ, G, SP, M, L |

| Usage | slurry pump part |

| Shaft Seal | N/A |

Product Detail

Submersible vertical slurry pump price, mud pump

Product Description

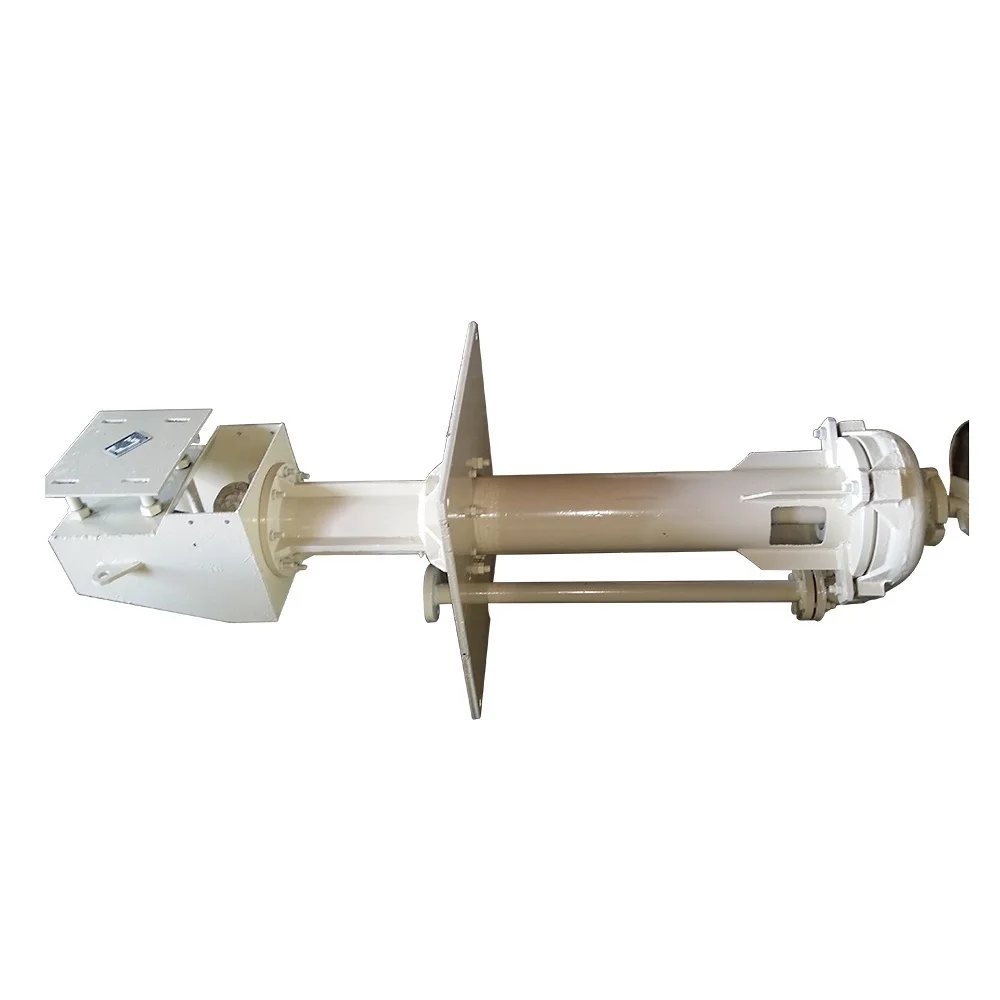

Vertical submersible sump slurry pumps are vertical and centrifugal slurry pumps, which work submerged to transport the abrasive and high-density slurry with large articles. The pumps have no need for any shaft seal and sealing water. They can also run under the conditions of inadequate suction duty.

Features :

1. SP (R) type submerged pumps are vertical centrifugal slurry pump, generally into the pool or pit to work,used to transport abrasive, coarse particle, high concentration slurry.

2. Don't need any shaft seal and shaft seal water, in the inhaled volume insufficient conditions they can also work normally.

3. SP (R) type submerged pumps' pump body is made of wear-resisting metal. Impeller is made of wear-resistant metal or rubber, polyurethane SP (R) type submerged pumps parts into the liquid with rubber lining,they are all applicable to transport corrosive slurry.

Product Application

Company Profile

Testing Equipment

Packaging & Shipping

FAQ

Q1.Can you supply pump qualified with ANSI and ASME standard?

A.Yes, our pump compliant with ISO / ASME/ANSI standard.

Q2.How can I purchase order without seeing the quality first?

A.If it is a big order, we can provide a sample for running testing at your plant.

Q3.How do you control the quality of the products?

A.Our production is strictly according to ISO 9001 standard and factory was established in 1980, have over 30 years experience in slurry pumps and parts.

Q4.How to customize pumps and mechanical seals ?

A.Customers could send us application data, we will select suitable pump and seal types, or client could send us drawings, We are well in OEM and ODM.

Q5.How can I pay for my items? What is the payment you can provide?

A.Usually by T/T, 30% down payment once PI confirmed, the balance will be paid after inspection and before shipment.

L/C at sight

Q6.How long is warranty?

A.1 year for main construction warranty.

Q7.How long is production leading time?

A.Normally 25 days. If client need urgently, we have a huge spare parts stock, we could finish assembly and testing in 7-15 days.

Q8.What is the shipping terms you can provide ?

A.Depends on customer's requirements, we can provide different transportation terms, such as EXW, FOB, CIF.

Q9.Who is in charge of after-sales?

A.Inside sales. It can save customer's time and high efficiency communicate. NNT has professional after sales service team, we will follow up the client's comments and suggest them good solutions. Solve client's problems and keeping the clients profit.

Q10.Who is in charge of maintenance?

A.Local agent. Client is first, if pump running has any problem on site, our local agent will arrival the plant within 24 hours.

contact us