Sand slurry submersible pumps 100m3/h submersible hydraulic sludge pump

Quik Detail

| Warranty | 1years |

|---|---|

| Customized support | OEM, ODM, OBM, Software reengineering |

| Brand Name | Pansto Pump |

| Model Number | ZJQ |

| Place of Origin | Hebei, China |

| Application | Commercial Buildings, Mining industry |

| Power Source | Electric |

| Pressure | Low Pressure |

| Structure | Single-stage Pump |

| Outlet Size | 40-300mm |

| Voltage | 380v |

| Power | 2.2-630kw |

| motor | Three phase asynchronous motor |

| Product name | Submersible Slurry Pump |

| Usage | Sludge |

| Standard or Nonstandard | NEMA Standard |

| Application scope | Mining Industry |

| Material | Cr27 |

| Packing | Plywood Packaging |

| Pump body | Cast Iron |

| Feature | Long Life |

| Function | Slurry Transmission |

Product Detail

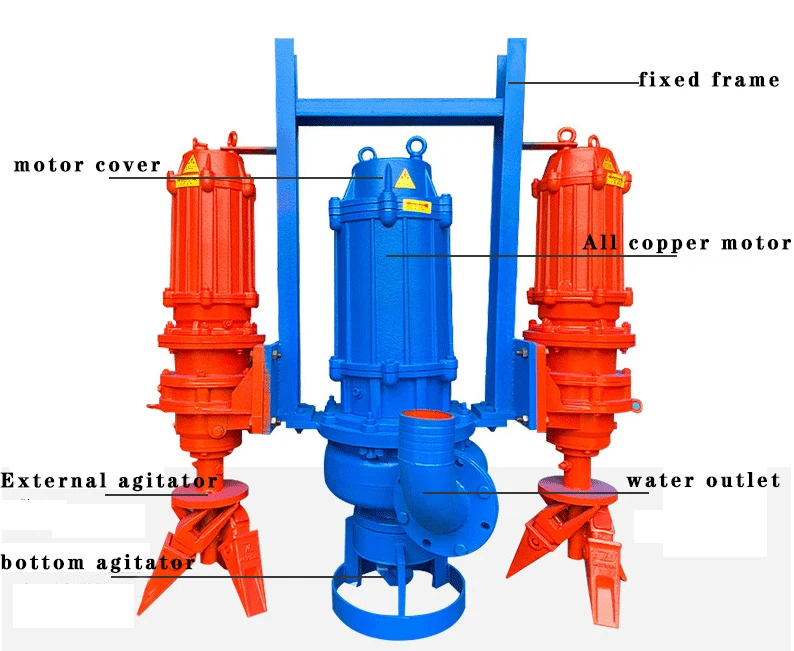

Sand slurry submersible pumps 100m3/h submersible hydraulic sludge pump

The Ultimate Solution for Vertical Slurry Transport

Sand slurry submersible pumps 100m3/h submersible hydraulic sludge pump are specifically engineered to handle the transfer of abrasive and high-density slurries in vertical sump applications. With their innovative design and exceptional performance, these pumps provide reliable and efficient slurry transport in various industries.

Key Features:

- Robust Design: Sand slurry submersible pumps 100m3/h submersible hydraulic sludge pump are constructed with durable materials that are resistant to wear, corrosion, and impact, ensuring long-lasting performance even in the harshest environments.

- Vertical Configuration: The pumps are designed for installation in vertical sumps or tanks, making them suitable for applications where space is limited or where submerged operation is required.

- High Efficiency: Equipped with advanced hydraulic technology, these pumps offer high efficiency, optimizing the delivery of slurries while minimizing energy consumption.

- Wide Range of Applications: Sand slurry submersible pumps 100m3/h submersible hydraulic sludge pump are widely used in industries such as mining, mineral processing, coal preparation, chemical processing, and more. They can handle abrasive, corrosive, and high-density slurries effectively.

- Versatile Performance: With a range of impeller options and customizable configurations, these pumps can adapt to various operating conditions and handle a wide range of solids concentrations and particle sizes.

- Reliable Operation: Sand slurry submersible pumps 100m3/h submersible hydraulic sludge pump are designed and manufactured to ensure reliable performance and minimal downtime. Their robust construction and precision engineering make them dependable even in demanding applications.

- Easy Maintenance: The design of these pumps allows for easy access to critical components, simplifying maintenance tasks such as impeller and liner inspection or replacement.

Applications:

Sand slurry submersible pumps 100m3/h submersible hydraulic sludge pump are used in a wide range of applications, including:

- Mining and Mineral Processing: They are ideal for transporting slurries containing minerals, ores, and other solid particles encountered in mining operations.

- Coal Preparation: Sand slurry submersible pumps 100m3/h submersible hydraulic sludge pump efficiently handle the transportation of coal slurries, contributing to the coal washing and separation processes.

- Chemical Processing: They effectively handle corrosive slurries encountered in chemical production and processing.

- Aggregate Processing: These pumps play a vital role in handling sand, gravel, and other abrasive materials in aggregate processing plants.

- Power Generation: Sand slurry submersible pumps 100m3/h submersible hydraulic sludge pump are used for transporting fly ash, bottom ash, and other residues generated during power plant operations.

Choose Sand slurry submersible pumps 100m3/h submersible hydraulic sludge pump for reliable, efficient, and low-maintenance vertical slurry transport. Contact us today to discuss your specific requirements and find the perfect solution for your application.