Sand Dredging Pump with Gear Box

Quik Detail

| Customized support | OEM, ODM |

|---|---|

| Brand Name | XINTUO |

| Model Number | WN |

| Place of Origin | Hebei, China |

| Application | Marine, Metal and Equipment Manufacturers, Mining industry, Raw Water Intake, Wastewater Transport and Flood Control, wastewater treatment |

| Horsepower | 100 |

| Power Source | Electric |

| Pressure | 10 |

| Structure | Single-stage Pump, Single-stage |

| Cable Length | 10m |

| Outlet Size | 8''-24'' |

| Voltage | 380V, 415V or as required |

| Certification | ce |

| Usage | Sand suction, Sludge suction, Dredger |

| Theory | Centrifugal |

| Outlet dia | 18'' Inch |

| Connection | V-belt,Elastic coupling, Gear reducer,Fluid Coupling |

| Shaft Seal | Gland Packing seal,Expeller seal, Mechnical seal |

| Color | Customers' Requirement |

| Certificate | CE ROHS |

| Material | Cr27 |

Product Detail

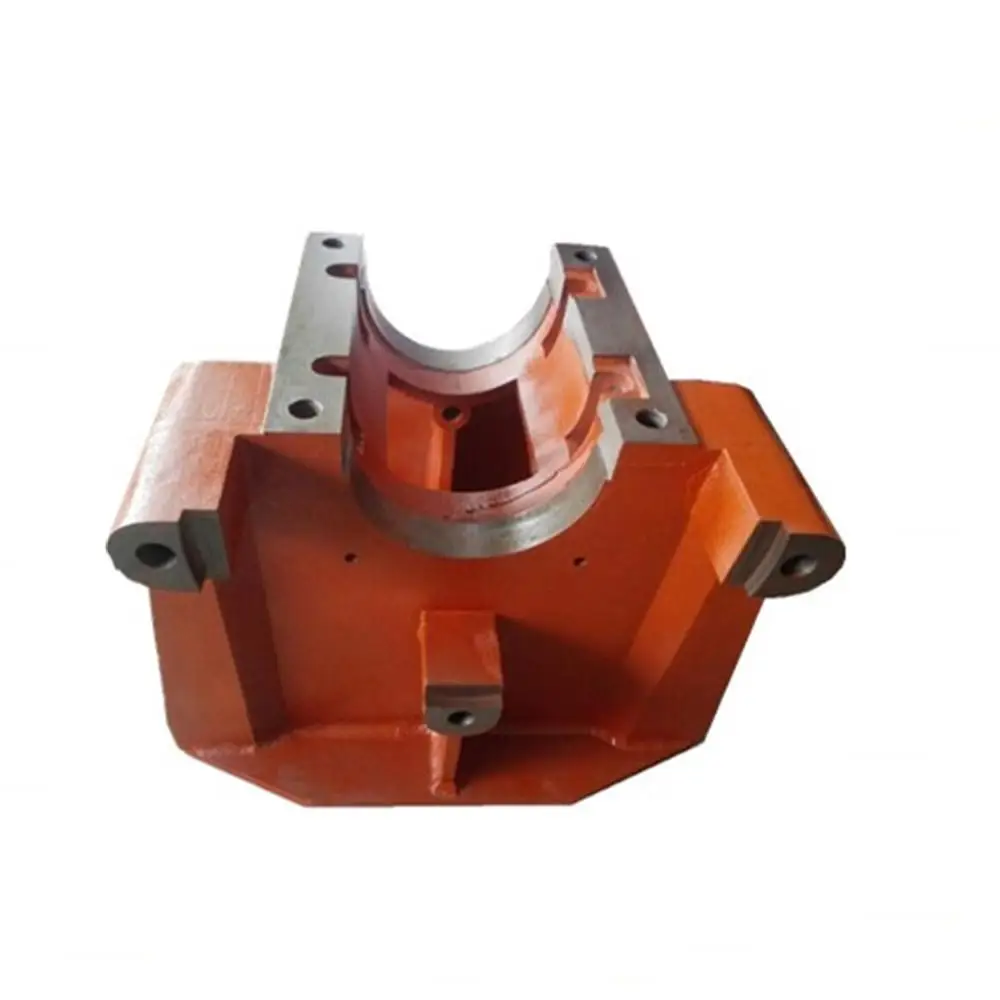

Sand Dredging Pump with Gear Box

Product Description

Product Description :

WN pump is a new type of sludge pump aiming at rivers and seas out of repair.

WN pump is a single-stage single suction cantilever horizontal centrifugal pump

Features

1. Large dredging depth, high density of dredging mud, good NPSH and strong suction lift ability

2. Strong through-put. The pump can presistently discharge gravel, high plastic soil lump,etc

3. The pump can be directly matched with either motor or diesel engine

4. Wide applications. It can be used in various kinds of soil quality.

Generally, the pump is matched with an impeller with 3 or 5 pieces of vane.

At the same time, the impellers can be provided with various diameters and vane types to suit

kinds of working conditions.

5. Little hydraulic loss, high efficiency and low oil-consumption

6. Little volume, light weight

7. Steady operating, little vibration, low noise

8. Simple & reliable constrution, easily disassembly & assembly,convenient maintaince

9. Reliable sealing without leakage

10. Long operating life of parts

11. Light weight, good wear-resistance

12. Super dredging performance, perfectly suited for the dredge on the whole construction, high

multiple economy benefits

Product Application

This Series of Pumps are used conveying abrasive or corrosive slurry, especially clinker of power plants in

electric power, metallurgy, mining, coal, building materials, chemical industry and other industrial sectors,etc.

Company Profile

Testing Equipment

Packaging & Shipping

FAQ