New slurry pump parts ceramic pump parts for high abrasive and corrosive medium

Quik Detail

| Warranty | 12 months, 1 Year |

|---|---|

| Customized support | OEM, ODM, OBM, Software reengineering |

| Brand Name | XINTUO |

| Model Number | HH, G, L, M, SP, ZJ |

| Place of Origin | Hebei, China |

| Application | Industrial Boilers, Industrial Utilities, Machining, Marine, Metal and Equipment Manufacturers, Mining industry, Pharmaceutical industry, Mining slurry, Mining flotation |

| Horsepower | 200hp |

| Power Source | Electric |

| Pressure | High Pressure |

| Structure | Single-stage Pump |

| Cable Length | 100m |

| Outlet Size | 8inch |

| Voltage | 400V |

| Power | 160KW |

| motor | IP68 |

| Product Type | Slurry pump parts |

| Product name | slurry pump parts ceramic pump parts for high abrasive and corrosive |

| Material | Rubber/ Polyurethane/Ceramic |

| Usage | HH, G, L, M, SP, ZJ, ZJL, ZJQ WN, TL slurry pump |

| Colour | Customized |

| Certificate | ISO9001 |

| Feature | Corrosion Resistant |

| OEM | Available |

| Advantage | Highly anti-abrasive and anti-corrosive |

Product Detail

New slurry pump parts ceramic pump parts for high abrasive and corrosive medium

Product Description

Brief introduction for slurry pump parts

Composite ceramic is our latest developed technology.

Most cost-effective slurry pump material in domestic .

Improves service life 3-5 times over A05 material, and 2–3 times over natural rubber on resisting abrasive and corrosive slurries.

Its properties of cavitation damage resistance even 10 times over others.

Ceramic material performance:

HRC: >90 (Hardness close to diamonds)

PH of working condition: 1-14

Working temperature: -40-120℃

Coefficient of dilatation: 1-3%

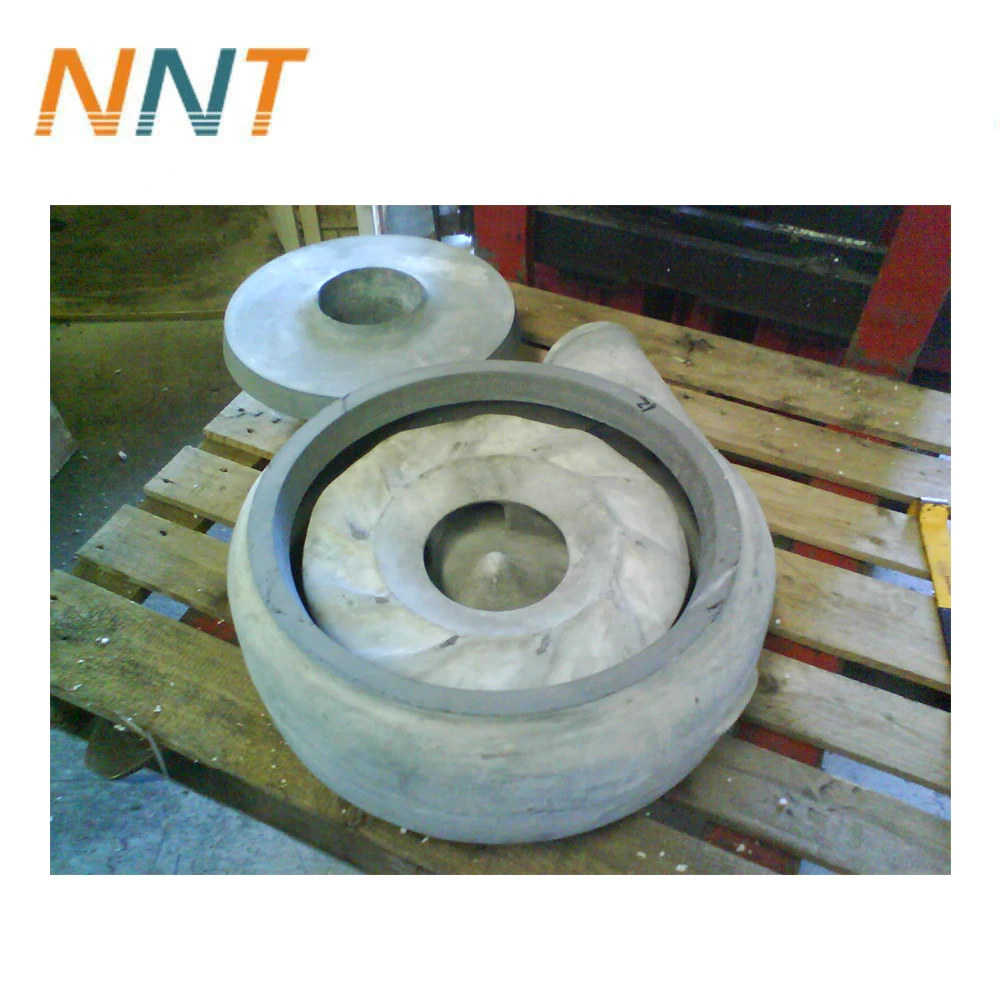

Basic manufacturing process:

1. Mixing, casting in vacuum

2.Heat treatment

3.Tempering

4.Clean up

The advanced casting process overcomes the brittle characteristics of the sintered ceramics, increased the elasticity of the material. Easy for maintenance and installation, increases the impact resistance of the pump, which enables the ceramic material to be applied in the ceramic slurry pump parts.

We also provide OEM ceramic slurry pump parts service according to customer's special requirements .

No.

Name

Codes

1

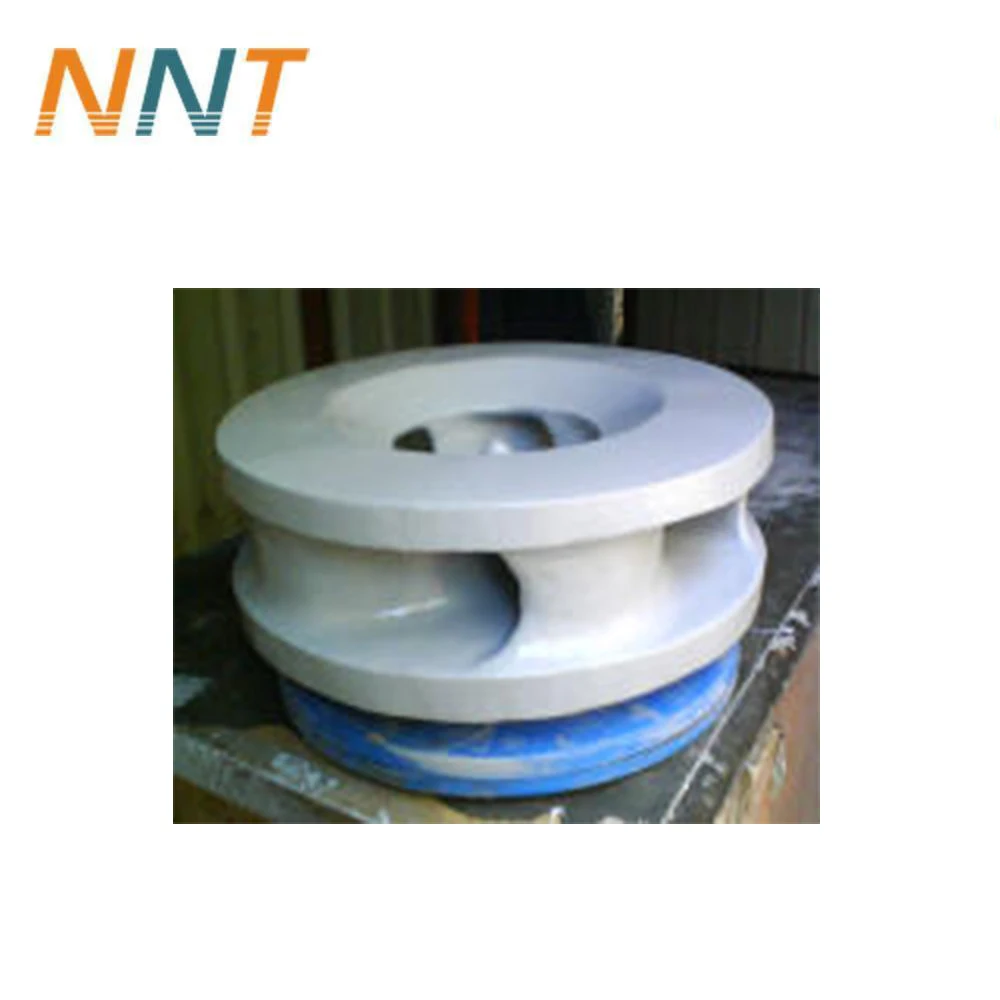

Pump Impeller

127, 147, 145, etc., such as C2127, D3147, E4147, F6147, G8147, G10147, FAM1247

2

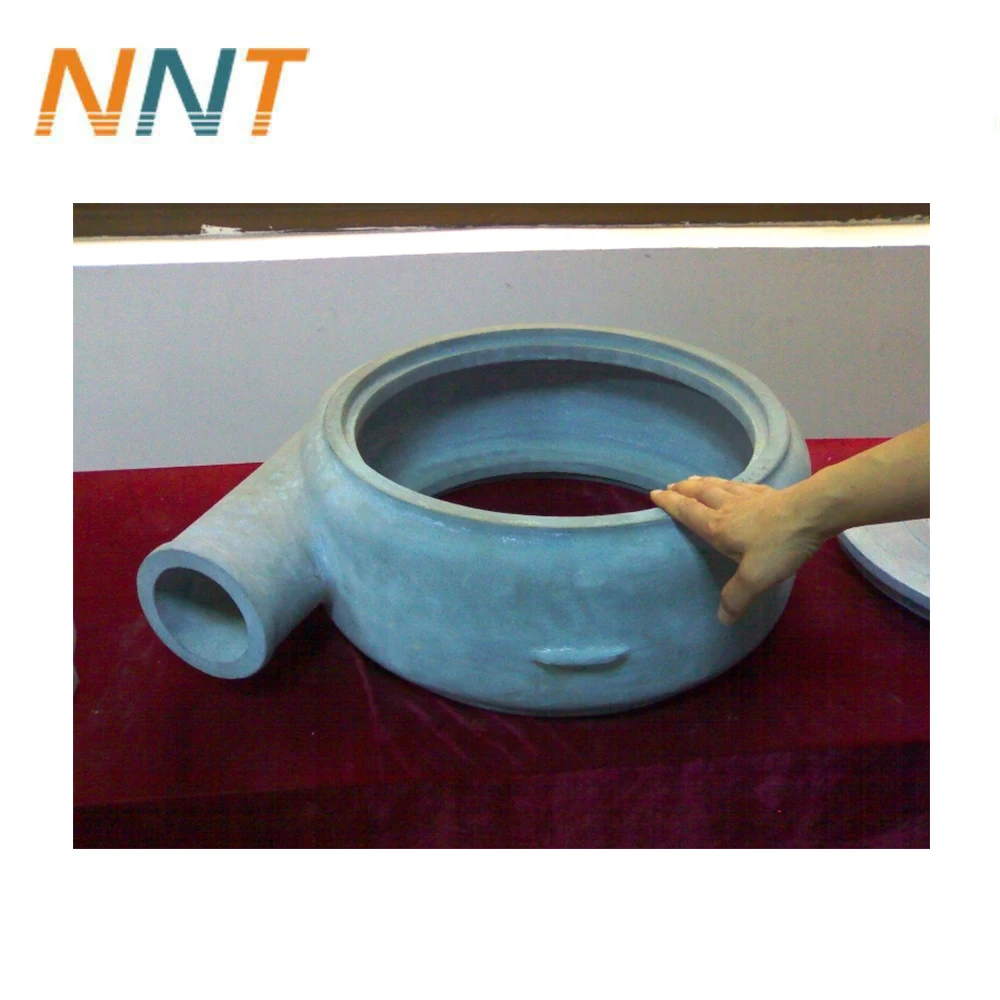

Volute / casing

C2110, D3110, E4110, F6110, G10110, G12110, …

3

Frame & Bearing Assembly

B, C, D, E, F, R, X, ST, T, TU, CC, DD, EE, FF, etc.

About XINTUO