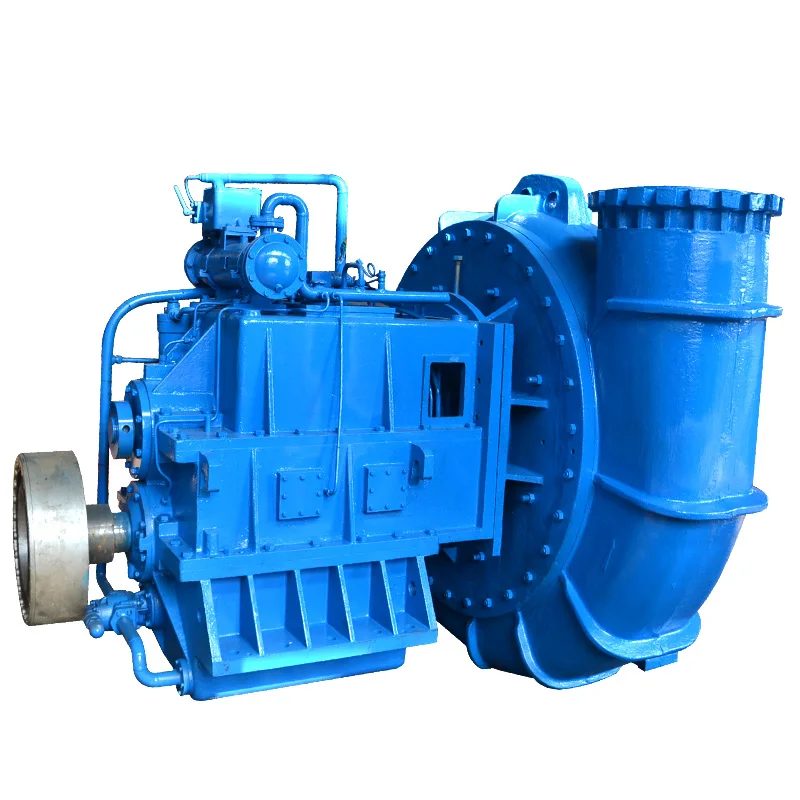

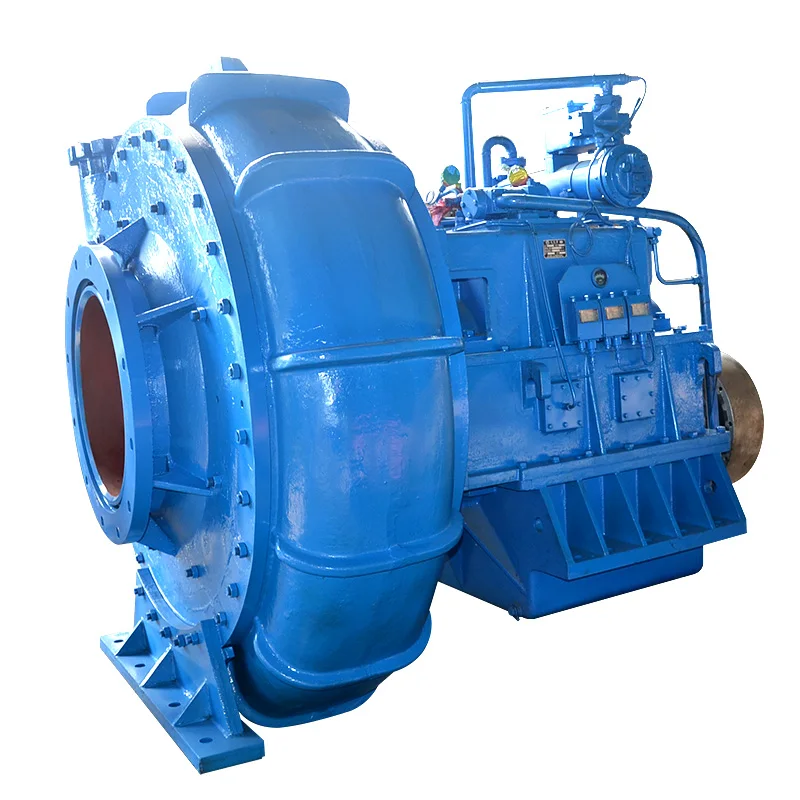

Large flow sand suction dredge pump for sand suction and dredging marine works

Quik Detail

| Warranty | 12 months |

|---|---|

| Customized support | OEM, ODM, OBM, Software reengineering |

| Brand Name | Xintuo |

| Model Number | WN |

| Place of Origin | Hebei, China |

| Application | Biofuel Industry, District Energy, Industrial Utilities, Marine, Metal and Equipment Manufacturers, Mining industry, Sand suction, Sand dredge, Dredging, Mud, sludge, slurry, soil, gravel dredging in river, sea,sumps, basins |

| Horsepower | 1000hp |

| Power Source | Diesel Engine |

| Pressure | High Pressure |

| Structure | Single-stage Pump |

| Cable Length | Customized |

| Outlet Size | 300mm |

| Voltage | 380V-660V, 380V/400V/440V |

| Power | 750KW |

| motor | IP68 |

| Product Type | Sand suction dredge pump |

| Product name | Large flow sand suction dredge pump for sand suction and dredging |

| Material | High Chrome Alloy |

| Color | Customized |

| Feature | High Flow |

| Motor | IP68 |

| Seal | Packing seal, mechanical seal |

| Usage | Mud, sludge, slurry, soil, gravel dredging in river, sea,sumps, basins |

Product Detail

Product Description

Large flow sand suction dredge pump for sand suction and dredging marine works

Construction

200WN to 500WN Sand suction dredge pump are of single casing, single stage cantilevered horizontal centrifugal

pumps. Two types of coupling with gear box: frame and pump box.

600WN to 1000WN Sand suction dredge pump are of double casings, single stage cantilevered centrifugal pumps.

These pumps are equipped with frame and lubrication is force thin oil. The design of double casing the

pump working till the volute liner almost worn down and guarantee no leakage when volute liner is worn down.

Easy Uninstallation & Convenient Maintenance

Sand suction dredge pump is of front uninstallation construction to make uninstall easily and convenient maintenance. And special tools are equipped for uninstalling the parts.

Standard four-head trapezoid thread connection between impeller and shaft can transfer powerful torsion and be convenient to uninstall. Impeller uninstall ring at shaft sleeve side also make the impeller

uninstallation much easier.

Good Performance

Good NPSH can not only guarantee suction but also make deep dredge and high allowable suction

density. Minimum NPSH: 4m.

With wide impeller passage, pump can continuously pump gravel or high plastic clay without clogging.

Max allow particle size: 350mm.

Performance curves descend obviously to make pumps adopt pipeline distance changes.

By changing the impeller diameter or impeller rotating speed, it can easily change the discharge with

the same flow rate.

Material

WN Sand suction dredge pump Material of wet parts is high wear resistant high chrome alloy.

Considering the maintenance, wear resistant parts are nearly of the same wear life to reduce maintenance & interchange costs.

Low Hydraulic loss, High efficiency, Energy Saving

Efficiency of WN is 2 or 3 percentage higher than other common pumps.

Reliable Shaft Seal, No leakage

Shaft Seal types of 200WN to 500WN: Mechanical seal, packing, or combination of mechanical and packing

600WN to 1000WN uses helical casing L rubber seal which is made of 3 pieces of L seal ring and one

special thread shaft sleeve.

Features of WN Sand suction dredge pump

*Adopted high chrome impeller, suction cover and agitator as standard supplies.

*High efficiency and quality motor in a rigid structure ensures long durability.

* Adopted top quality mechanical seal.

*Easy operation, handling and maintenance.

Applications for WN Sand suction dredge pump

*Dredging sand slurry gravel soil sludge mud paste mire slime slush at river, river mouth and sea floor

*Transferring sand, slurry, gravel, soil, sludge at mine, civil works, construction sites, ready mixed concrete factory, recruiting construction materials factory and power plant etc.

*Removal sediment from sumps or basins.

About Nainater

Our company was reformed from Shijiazhuang Baifo Foundry Factory which was a national collective enterprise. We are a modern pump industry enterprise engaged in professional manufacture, scientific research, development, sales and service. Our company is specialized in manufacturing: slurry pump and slurry pump parts, dredging pump and dredging pump parts, desulfurization pump and desulfurization pump parts, clean water pump and sewage pumps which are widely used in mine, metallurgy, coal, electric power, dredge and other sectors of the national economy. These pumps are sold to South America, Africa, Southeast Asia, Russia and so on more than 20 countries and regions. Our products have won unanimous favorable comments from the market. With advanced design concepts as the vanguard, excellent product quality as the foundation, rich experience in production as powerful backing, and meeting the market demand as the goal, Shijiazhuang Xintuo Slurry Pump Co., Ltd. promises to supply the best quality equipment and superior services. We build a wide selection of quality engineered, highly reliable and truly innovative pumps. Whether your application calls for a pump to be submersible, vertical cantilever, line shaft, horizontal or high pressure, we have the right pumps for your job. We are proud to offer an all-round service to our customers, from supply and installation, to after sales support and on-going maintenance. As a result of our commitment to providing quality service, our company has experienced continued business growth and exhibits a strong base of satisfied customers.