Horizontal Self Priming Slurry Pumps Filter Press Feed Pump With Electric Motor Driven

Quik Detail

| Warranty | 1years |

|---|---|

| Customized support | OEM, ODM, OBM |

| Brand Name | Pansto Pump |

| Model Number | Filter Press Pumps |

| Place of Origin | Hebei, China |

| Application | Biofuel Industry, Developing World Water Solutions, District Energy, Drinking water treatment, Irrigation and Agriculture, Marine, Mining industry, Raw Water Intake, Wastewater Transport and Flood Control, wastewater treatment, Water Distribution, Water Treatment Solutions |

| Power Source | Electric |

| Pressure | Low Pressure |

| Structure | Single-stage Pump |

| Cable Length | customize |

| Outlet Size | 3-500mm |

| Voltage | 220v/380v |

| Power | 15-110kw |

| motor | Three-phase asynchronous motor |

| Product name | Submersible Slurry Pump |

| Usage | Slurry |

| Material | Cast Iron |

| Keywords | Filter Press Pumps |

| Color | Customer Specifications |

| MOQ | 10 piece |

| Size | Customized Size |

| Packing | Wooden Case |

| Advantage | Environment Protection |

| Type | Centrifugal Pump |

Product Detail

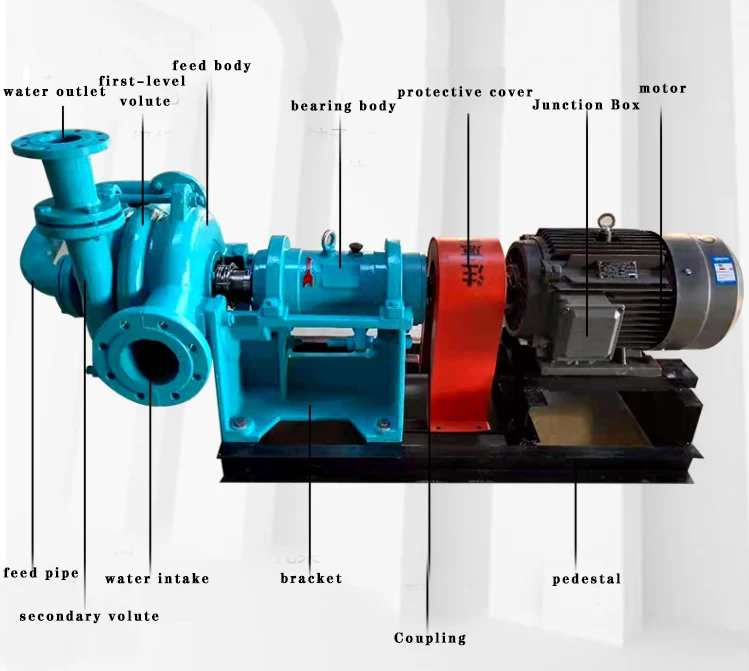

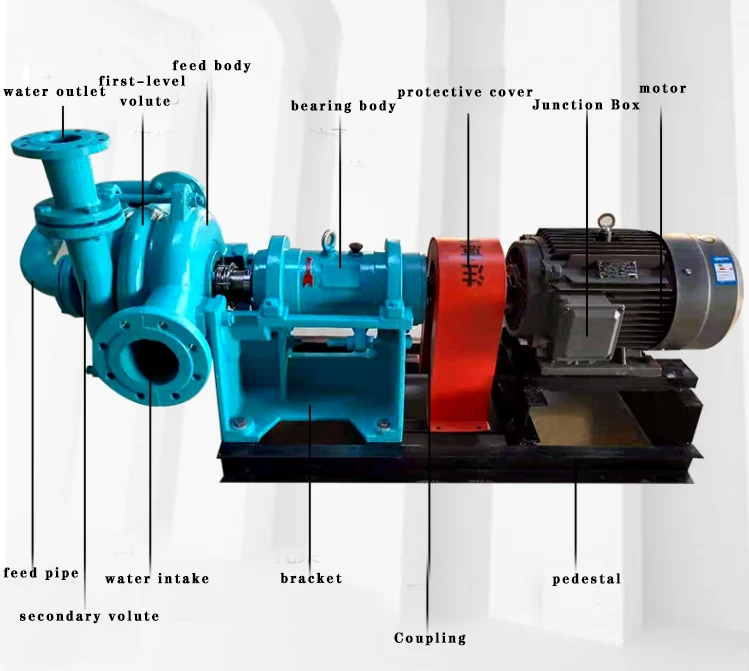

Horizontal Self Priming Slurry Pumps Filter Press Feed Pump With Electric Motor Driven

The Ideal Solution for Efficient Sand Handling

Horizontal Self Priming Slurry Pumps Filter Press Feed Pump With Electric Motor Driven, also known as Horizontal Slurry Pumps, are specifically designed to handle the transport of sand and other abrasive materials. With their superior performance and rugged construction, these pumps are the perfect choice for various applications requiring efficient sand handling.

Key Features:

- Durable Design: The pump is constructed with high-quality materials that are resistant to wear, corrosion, and impact, ensuring long-lasting performance in demanding environments.

- Horizontal Configuration: The horizontal design allows for easy installation, maintenance, and operation. It eliminates the need for complex alignment and provides convenience in connecting to the pipeline.

- High Efficiency: Equipped with advanced hydraulic mechanisms, these pumps deliver high efficiency, minimizing energy consumption while maximizing the transport of sand and other abrasive materials.

- Wide Range of Applications: Horizontal Self Priming Slurry Pumps Filter Press Feed Pump With Electric Motor Driven find applications in industries such as mining, dredging, aggregate processing, and more. They are suitable for handling sand, gravel, slurry mixtures, and various abrasive solids.

- Versatile Performance: These pumps can efficiently handle a wide range of particle sizes and concentrations. With various impeller and liner options, they offer flexibility to adapt to different operating conditions.

- Reliable Operation: Designed for reliable performance, the pumps undergo rigorous testing and are built to withstand harsh conditions. This ensures minimal downtime and reduces maintenance costs.

- Easy Maintenance: The design of Horizontal Self Priming Slurry Pumps Filter Press Feed Pump With Electric Motor Driven allows for easy access to critical components, simplifying maintenance tasks such as impeller and liner inspection or replacement.

Applications:

Horizontal Self Priming Slurry Pumps Filter Press Feed Pump With Electric Motor Driven are widely used in a variety of applications, including:

- Mining and Mineral Processing: These pumps efficiently handle the transport of sand, ores, and other solids encountered in mining and mineral processing operations.

- Dredging: They are ideal for dredging projects that involve the removal and transport of sand, sediment, and other materials from bodies of water.

- Aggregate Processing: Horizontal Self Priming Slurry Pumps Filter Press Feed Pump With Electric Motor Driven are commonly used in aggregate processing plants to handle the transportation of sand and gravel.

- Construction: They play a crucial role in construction projects involving sand and other abrasive materials.

Choose Horizontal Self Priming Slurry Pumps Filter Press Feed Pump With Electric Motor Driven for reliable, efficient, and low-maintenance sand handling. Contact us today to discuss your specific requirements and find the perfect solution for your application.