High Chrome Alloy Mining Vertical Slurry Pump

Quik Detail

| Customized support | OEM, ODM |

|---|---|

| Brand Name | XINTUO PUMP |

| Model Number | SP Vertical Slurry Pump |

| Place of Origin | China |

| Application | Metal and Equipment Manufacturers, Mining industry, Wastewater Transport and Flood Control, wastewater treatment |

| Horsepower | 40-300 |

| Power Source | Electric |

| Pressure | 10 |

| Structure | Single-stage Pump, Single-stage |

| Outlet Size | 40-350mm |

| Voltage | 380V, 415V or as required |

| Power | 30-220kw, Electric |

| Product name | Mining Slurry Pump |

| Theory | Centrifugal |

| Connection | V-belt,Elastic coupling, Gear reducer,Fluid Coupling |

| Material | natural ruber or high-chrome alloy |

| Shaft Seal | Gland Packing seal,Expeller seal, Mechnical seal |

| Usage | mining, metallurgy,chemical processing |

| Color | Client's Requirements |

| Certification | CE |

Product Detail

High Chrome Alloy Mining Vertical Slurry Pump

Product Description

Product Description :

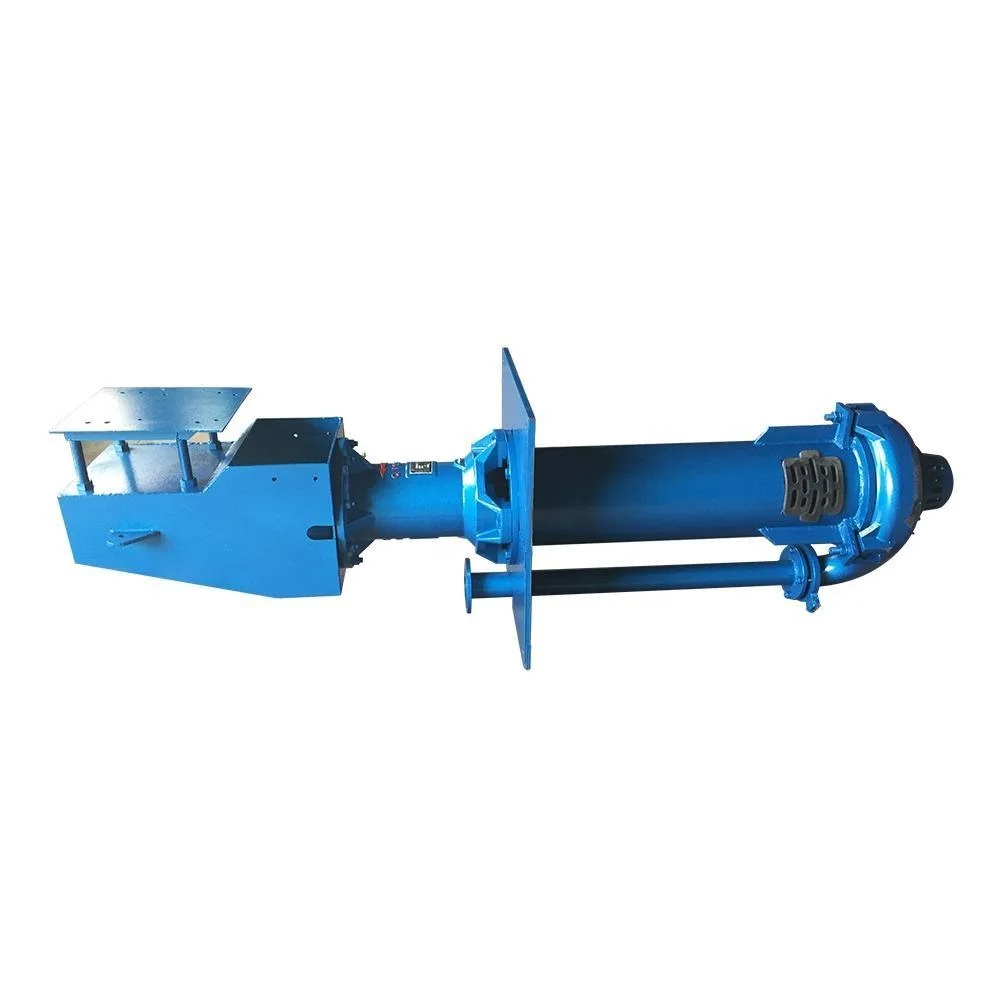

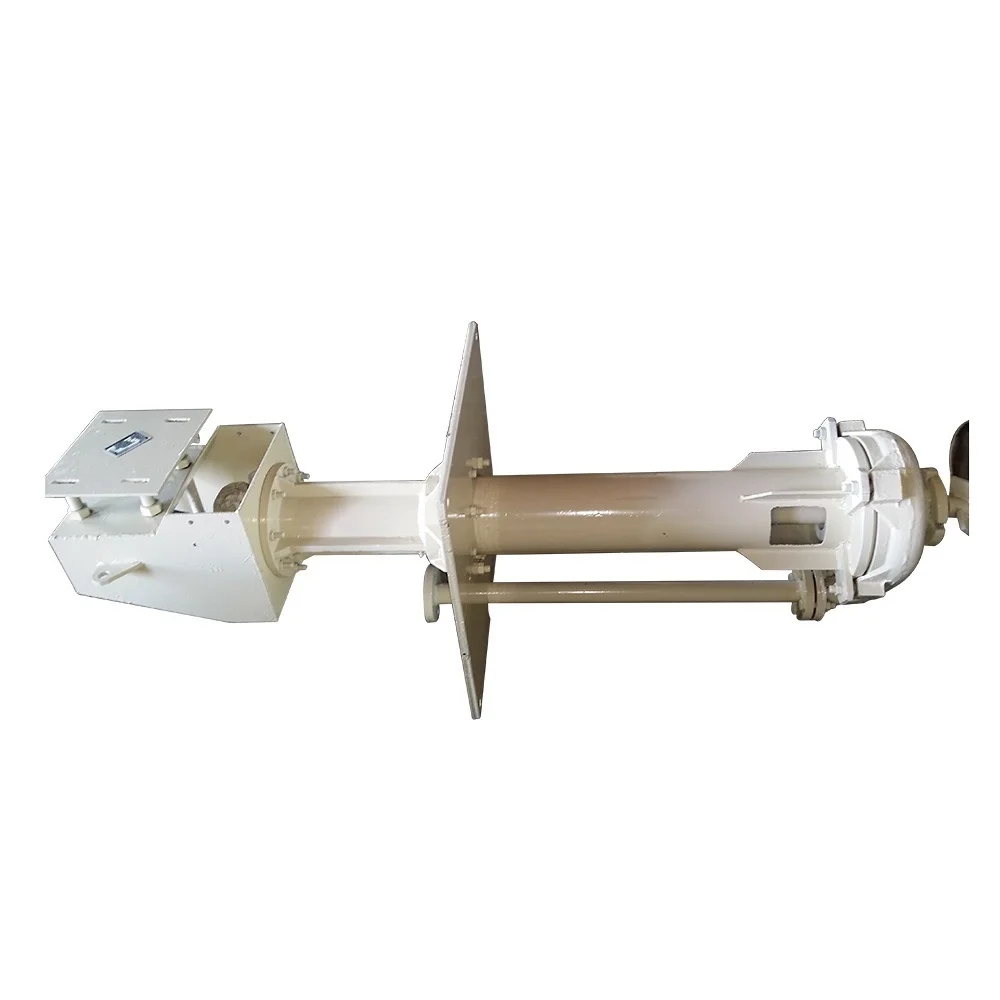

SP series centrifugal slurry pumps are cantilevered, vertical, centrifugal slurry pumps.

The SP/SPR heavy duty cantilever sump pump is designed for applications requiring greater reliability and durability than conventional vertical process pumps can offer.

Fully elastomer lined or hard metal fitted. No submerged bearings or packing. High capacity double suction design. Optional recessed impeller and suction agitator available.

Features :

1.SP (R) type submerged pumps are vertical centrifugal slurry pump, generally into the pool or pit to

work,used to transport abrasive, coarse particle, high concentration slurry.

2. Don't need any shaft seal and shaft seal water, in the inhaled volume insufficient conditions they

can also work normally.

3.SP (R) type submerged pumps' pump body is made of wear-resisting metal. Impeller is made of

wear-resistant metal or rubber, polyurethane SP (R) type submerged pumps parts into the liquid with

rubber lining,they are all applicable to transport corrosive slurry.

Product Application

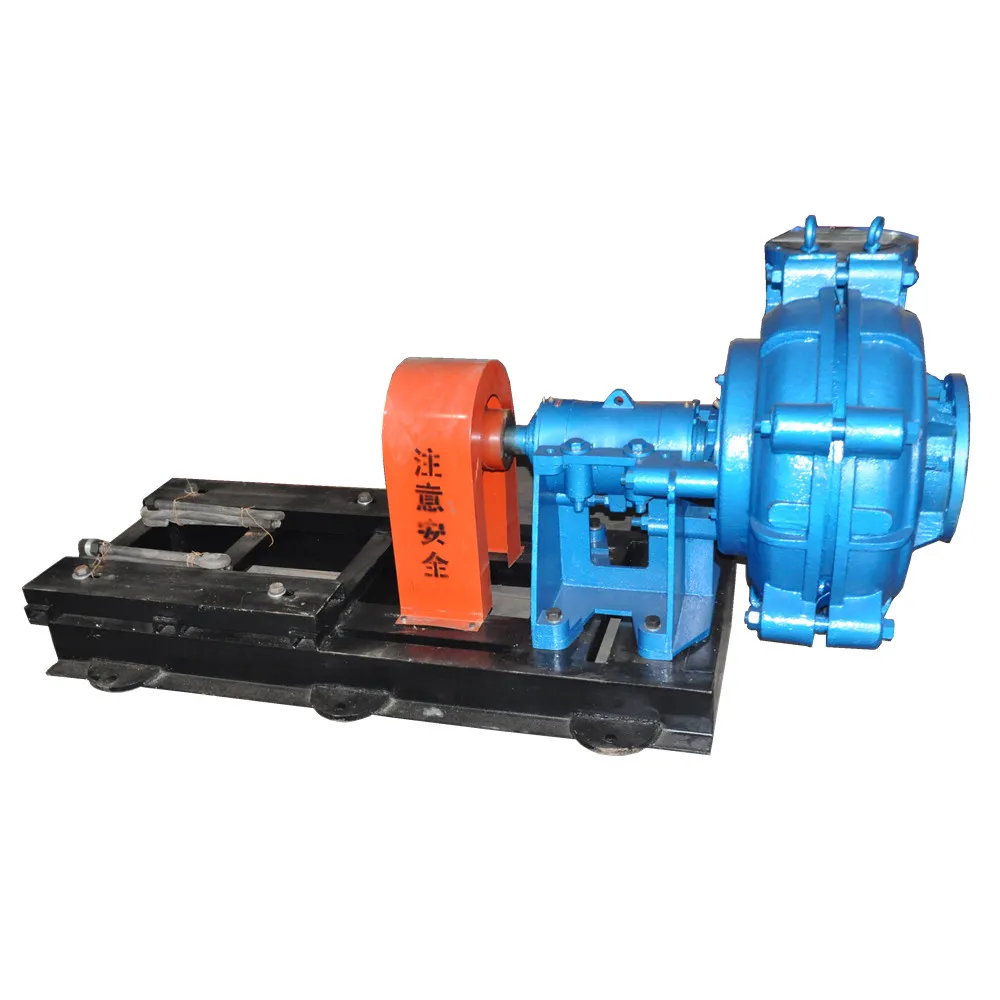

The rugged SP/SPR Heavy Duty Sump Pumps are available in a wide range of popular sizes to suit most pumping applications. Thousands of these pumps are proving their reliability and efficiency worldwide in:

• Minerals processing

• Coal preparation

• Chemical processing

• Effluent handling

• Sand and gravel

and almost every other tank, pit or hole-in-the-ground slurry handling situation.

Company Profile

Testing Equipment

Packaging & Shipping

FAQ