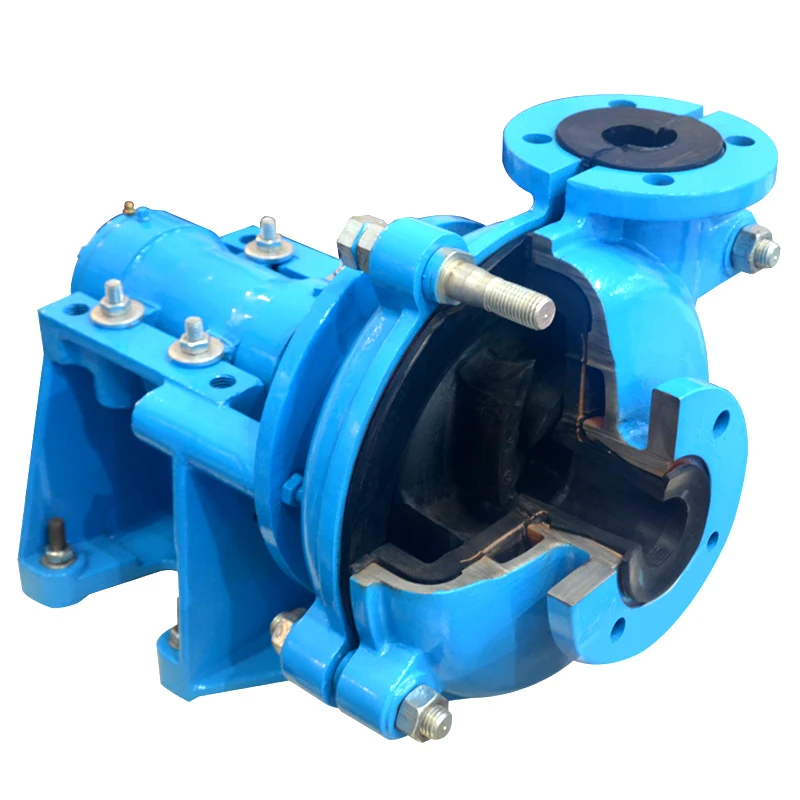

Centrifugal Chemical Processing FGD Slurry Pump Manufacturer

Quik Detail

| Warranty | 1 year |

|---|---|

| Customized support | OEM, ODM |

| Brand Name | NNT |

| Model Number | TL series |

| Place of Origin | Hebei, China |

| Application | Metal and Equipment Manufacturers, Mining industry, Power plant FGD slurry pump |

| Horsepower | 2133 hp |

| Power Source | Electric |

| Pressure | 1-3 bar |

| Structure | Single-stage Pump |

| Outlet Size | 500-1000 mm |

| Voltage | 3/6 KV, etc. |

| Power | 1600 kw, Electric |

| Theory | Centrifugal Pump |

| model | TL series FGD slurry Pump |

| Name | Centrifugal Chemical Processing FGD Slurry Pump Manufacturer |

| color | white ,red or as required |

| liner | Natural rubber/A49 |

| Impeller | high chrome alloy A49 |

| stage | single stage |

| type | centrifugal horizontal pump |

Product Detail

Centrifugal Chemical Processing FGD Slurry Pump Manufacturer: High-Performance Pumping Solution

Overview

The Centrifugal Chemical Processing FGD Slurry Pump Manufacturer is a cutting-edge pumping solution specifically engineered for heavy-duty applications in mining, mineral processing, and other industrial sectors. With its robust design and exceptional performance, the Centrifugal Chemical Processing FGD Slurry Pump Manufacturer is widely recognized as a reliable choice for handling abrasive slurry with high efficiency.

Key Features

The Centrifugal Chemical Processing FGD Slurry Pump Manufacturer stands out with its impressive range of features that ensure reliable and efficient performance in challenging environments. With the pump being an integral component, it offers the following key benefits:

1. Durable Construction

The Centrifugal Chemical Processing FGD Slurry Pump Manufacturer boasts a rugged construction and is made from premium, wear-resistant materials. This robust design ensures long-lasting performance even under the harshest operating conditions. Its durability minimizes downtime and maintenance costs, making it a cost-effective solution.

2. Optimized Hydraulic Design

With its advanced hydraulic design, the Centrifugal Chemical Processing FGD Slurry Pump Manufacturer minimizes internal losses, resulting in improved efficiency and reduced energy consumption. It is engineered to deliver maximum flow and head, allowing for optimized performance while minimizing power requirements.

3. Interchangeable Parts

The Centrifugal Chemical Processing FGD Slurry Pump Manufacturer is designed with interchangeable parts, facilitating easy maintenance and repairs. Whether it’s replacing impellers, liners, or other components, the ability to interchange parts ensures quick turnaround times and minimal disruption to operations.

4. Wide Range of Sizes

Available in a wide range of sizes, the Centrifugal Chemical Processing FGD Slurry Pump Manufacturer can accommodate different flow rates and head requirements. Its versatility allows for customized solutions tailored to meet specific application needs, ensuring optimal performance and efficiency.

5. Efficient Solids Handling

The Centrifugal Chemical Processing FGD Slurry Pump Manufacturer is specifically designed to handle high concentrations of abrasive solids. Its robust design and specialized impeller allow for efficient transportation of slurry, without clogging or excessive wear. This pump minimizes maintenance requirements and maximizes productivity.

Applications

The Centrifugal Chemical Processing FGD Slurry Pump Manufacturer finds extensive use in various industries and applications, including:

Mining and Mineral Processing: Whether it’s transporting ore, tailings, or slurries during the extraction and processing of minerals, the Centrifugal Chemical Processing FGD Slurry Pump Manufacturer is a reliable choice.

Coal Preparation: The Centrifugal Chemical Processing FGD Slurry Pump Manufacturer effectively handles coal slurries, ensuring smooth operations in coal washing and handling processes.

Chemical Processing: In chemical plants, where corrosive and abrasive materials are encountered, this pump excels in delivering efficient performance.

Sand and Gravel: The Centrifugal Chemical Processing FGD Slurry Pump Manufacturer is capable of handling the transportation of sand and gravel slurries, making it an ideal solution for dredging and aggregate production.

Pulp and Paper: For pulp and paper manufacturing, the Centrifugal Chemical Processing FGD Slurry Pump Manufacturer provides excellent capabilities for transporting fibrous suspensions and waste materials.

Power Generation: From ash handling to flue gas desulfurization, the Centrifugal Chemical Processing FGD Slurry Pump Manufacturer plays a crucial role in power plant operations.

Centrifugal Chemical Processing FGD Slurry Pump Manufacturer Specifications

The Centrifugal Chemical Processing FGD Slurry Pump Manufacturer comes with the following specifications:

Maximum Flow Rate: [Insert Max Flow Rate]

Maximum Head: [Insert Max Head]

Motor Power: [Insert Motor Power]

Discharge Diameter: [Insert Discharge Diameter]

With its exceptional durability, superior performance, and wide range of applications, the Centrifugal Chemical Processing FGD Slurry Pump Manufacturer is the go-to choice for effective and reliable slurry transportation. Invest in the Centrifugal Chemical Processing FGD Slurry Pump Manufacturer and experience enhanced productivity and cost-efficiency in your operations. Contact us today to learn more about how the Centrifugal Chemical Processing FGD Slurry Pump Manufacturer can meet your specific requirements.